Whenever people hear about printing all they think of is ink and paper with a laser or an inkjet printer, but printing has gone beyond that. Some might think of it as science fiction, but with 3D printing technology you can print almost anything in 3 dimensions.

In this post am going to give you an overview of 3D Printing Technology or sometimes called Additive Manufacturing.

What 3D printing?

3D printing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the entire object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

How 3D Printing works

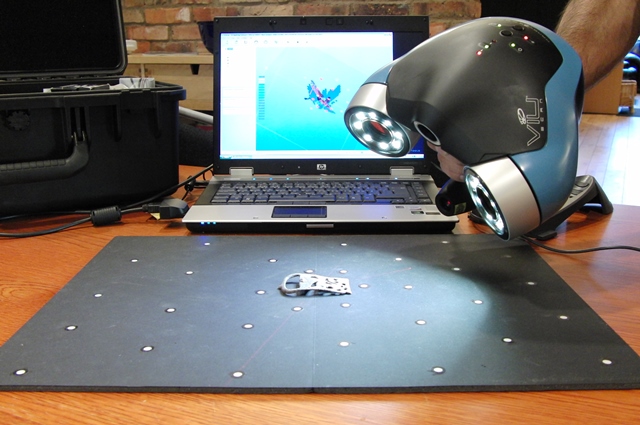

It all starts with making a virtual design of the object you want to create using a computer. This virtual design is made in a CAD (Computer Aided Design) file using a 3D modeling program or with the use of a 3D scanner (to copy an existing object). This scanner makes a 3D digital copy of an object and puts it into a 3D modeling program.

To prepare the digital file created in a 3D modeling program for printing, the software slices the final model into hundreds or thousands of horizontal layers. When this prepared file is uploaded in the 3D printer, the printer creates the object layer by layer. The 3D printer reads every slice (or 2D image) and proceeds to create the object blending each layer together with no sign of the layering visible, resulting in one three dimensional object.

Methods and technologies of 3D Printing

Not all 3D printers use the same technology to realize their objects. There are several ways to do it and all those available as of 2012 were additive, differing mainly in the way layers are build to create the final object. Some methods use melting or softening material to produce the layers. Selective laser sintering (SLS) and fused deposition modeling (FDM) are the most common technologies using this way of printing. Another method of printing is to lay liquid materials that are cured with different technologies. The most common technology using this method is called stereo lithography (SLA).

Selective laser sintering (SLS)

This technology uses a high power laser to fuse small particles of plastic, metal, ceramic or glass powders into a mass that has the desired three dimensional shape. The laser selectively fuses the powdered material by scanning the cross-sections (or layers) generated by the 3D modeling program on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

All untouched powder remains as it is and becomes a support structure for the object. Therefore there is no need for any support structure which is an advantage over SLS and SLA. All unused powder can be used for the next printing. SLS was developed and patented by Dr. Carl Deckard at the University of Texas in the mid-

1980s, under sponsorship of DARPA.

Animation of the SLS process

Fused deposition modeling (FDM)

The FDM technology works using a plastic filament or metal wire which is unwound from a coil and supplies material to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism, directly controlled by a computer-aided manufacturing (CAM) software package. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The software that comes with this technology automatically generates support structures if required. The machine dispenses two materials, one for the model and one form a disposable support structure.

The term fused deposition modeling and its abbreviation to FDM are trademarked by Stratasys Inc. The exactly equivalent term, fused filament fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

Stereolithography (SLA)

The main technology in which photopolymerization is used to produce a solid part from a liquid is SLA. This technology employs a vat of liquid ultraviolet curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and joins it to the

layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. The complete three dimensional object is formed by this project. Stereolithography requires the use of supporting structures which serve to attach the part to the elevator

platform.

This technique was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems.

Applications

Applications include design visualization, prototyping/CAD, metal casting, architecture, education, geospatial, healthcare and entertainment/retail.

Other applications would include reconstructing fossils in paleontology, replicating ancient and priceless artifacts in archaeology, reconstructing bones and body parts in forensic pathology and reconstructing heavily damaged evidence acquired from crime scene.

Source: 3Dprinting.com

Ousman Faal [Digital Vigilante] is a Tech Entrepreneur & Digital Skills Trainer who teaches both in the classroom and online. He has experience in various technologies and likes sharing it with others. Ousman has published 149 articles on this blog. He is the CEO of Faalen Technologies and Skills.gm.